What is beam strength formula

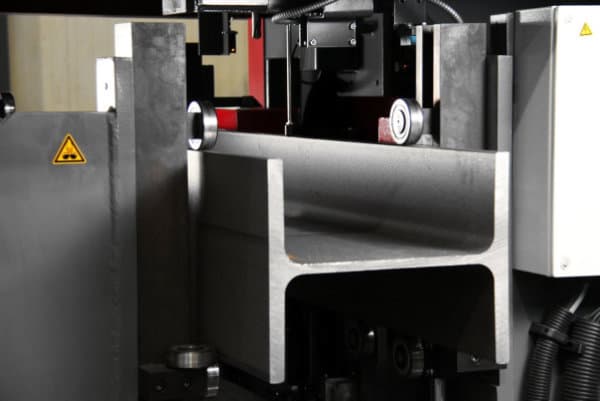

The Advantage-2 is powered by 25 HP (18.5kW) Siemens spindle motors. It has 3 drill spindles each with 5-station tool changers. This drilling technology is extremely efficient and allows for maximum operating time and excellent drill hole quality.

CNC Beam Drill Lines are the most cost-effective CNC beam drill lines on the current market. This allows fabricators to win more work, and makes more margin.