Band Saw Delta

Band Saw Safety Test

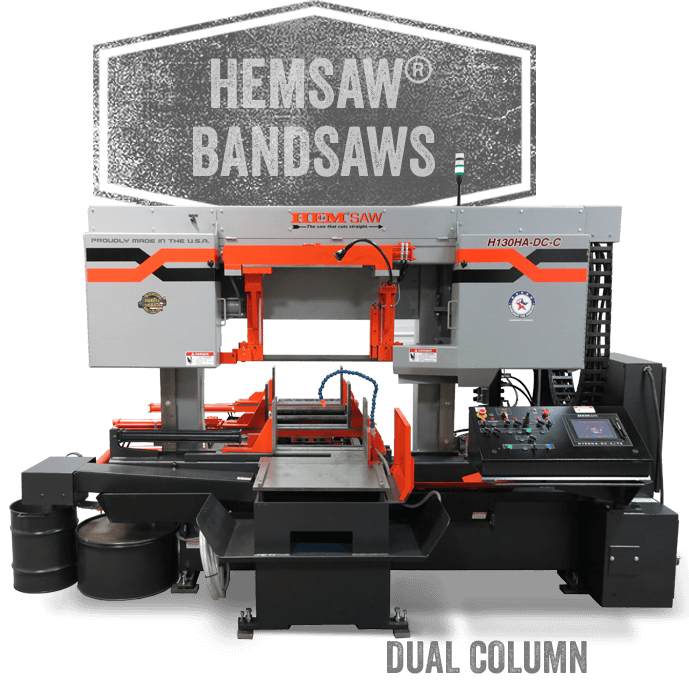

The solid cast iron wheels of the upper and lower 15-inch diameters help to create the momentum required for heavy-duty resawing projects. You can use the included foot brake to stop the saw in an emergency.

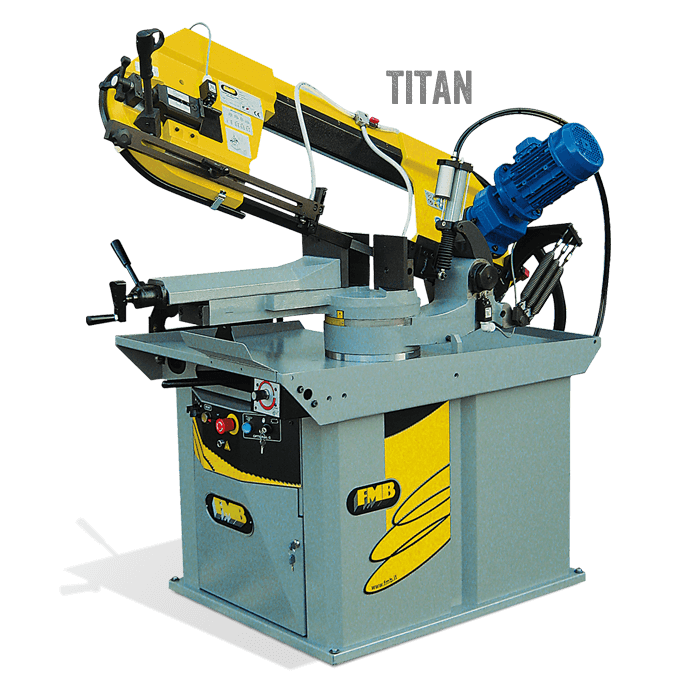

It is another machine with heavy duty that is capable of professional work. It has a built in halogen lamp.