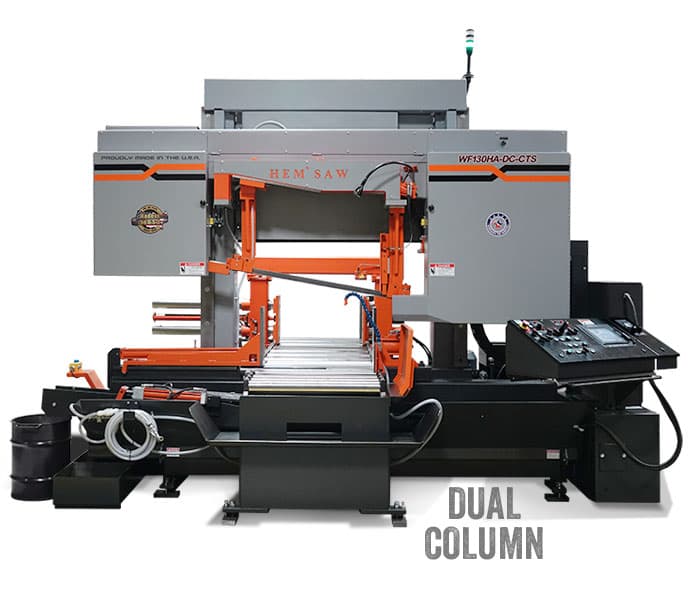

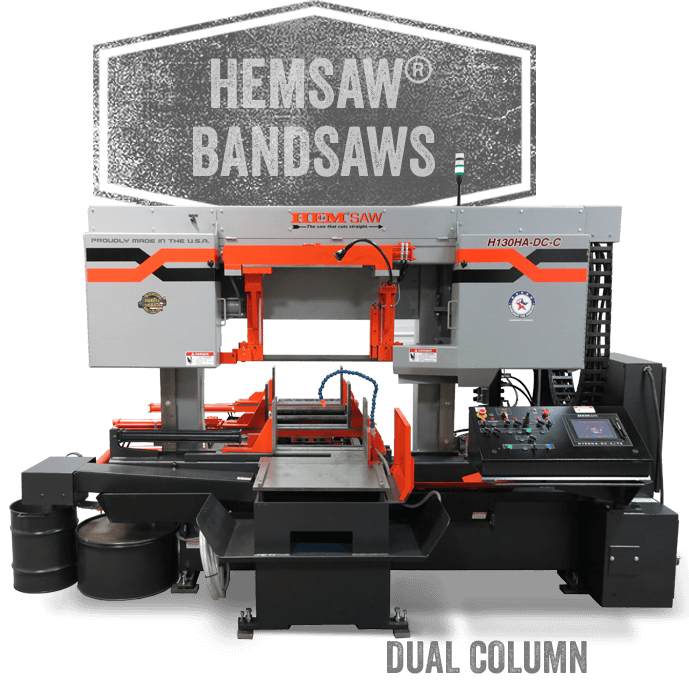

Band Saw Description

Band Saw Wood

The machine quickly gained popularity among builders and lumberyards once it was commercially manufactured.

It's possible to use the exact same saw to cut wood and metal. All you have to do is choose the appropriate blade.