Cosen Band Saws

Best Band Saws For The Money

You will receive a cut edge when you buy a piece from the mill. Sometimes it is better to recut them.

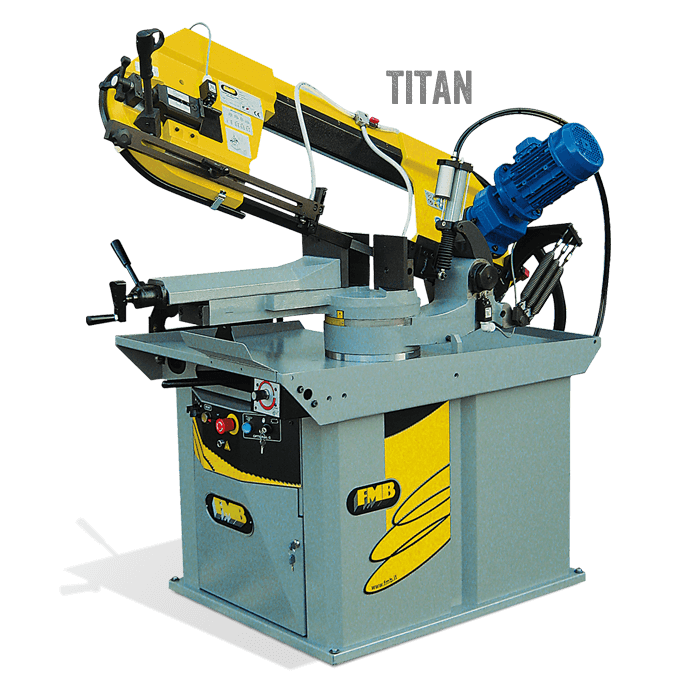

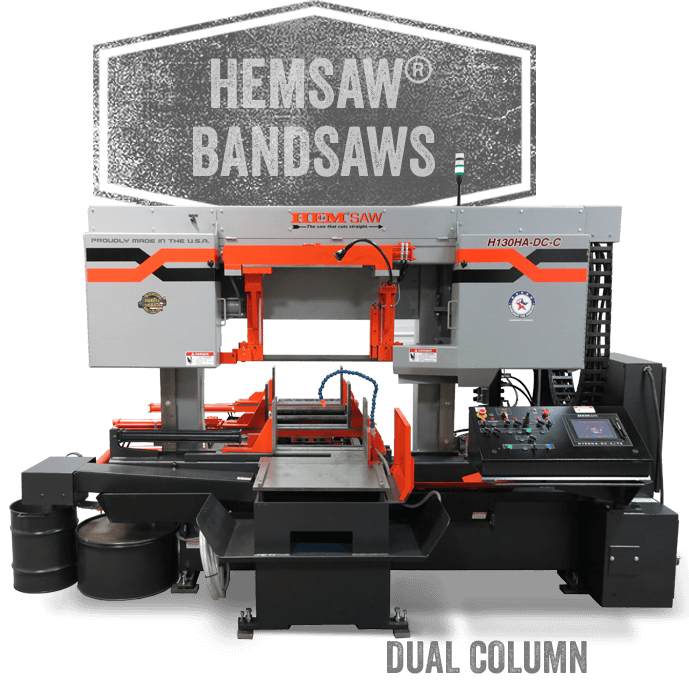

It is made from heavy gauge solid steel frames that are strong and durable. They also minimize vibration during operation.