Band Saws Australia

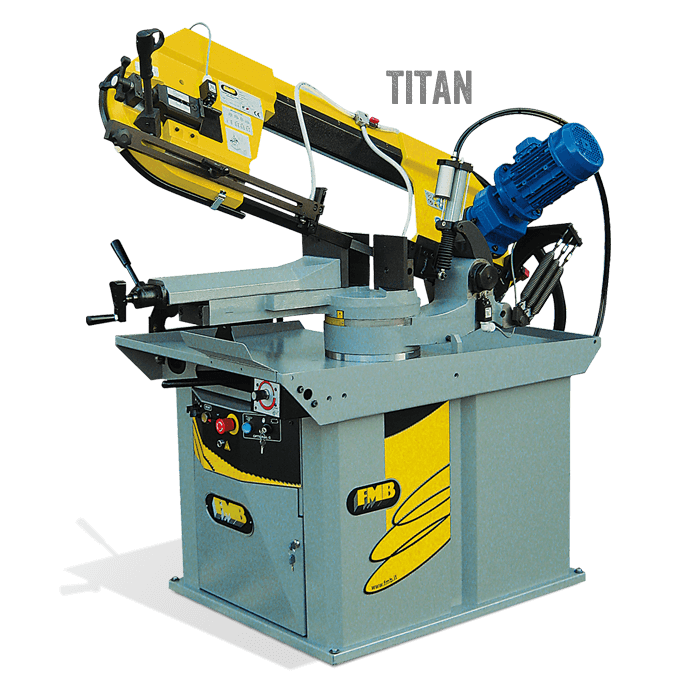

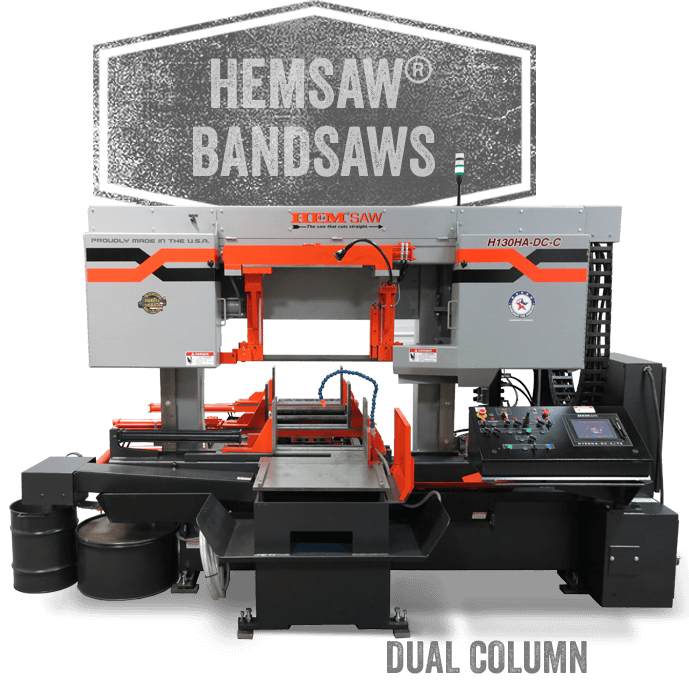

Horizontal Band Saws

The most common use of band saws is woodworking. This machine can do amazing things with wood.

Band saws can be used to work with wood in a variety of ways. The more you use them, the better your craft will be.