Band Saws Exercise

How do you shorten the line without touching

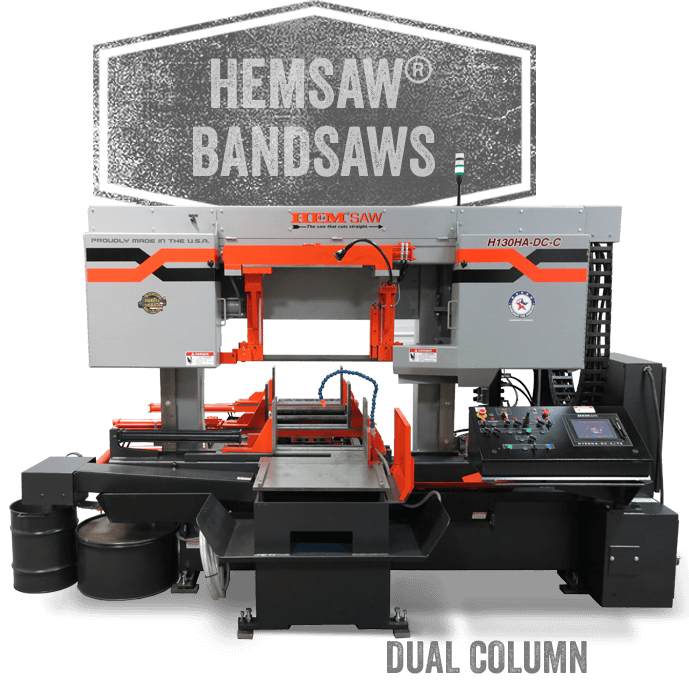

The band saw gives you the ability to control the grain, which can be used for effects in your new piece.

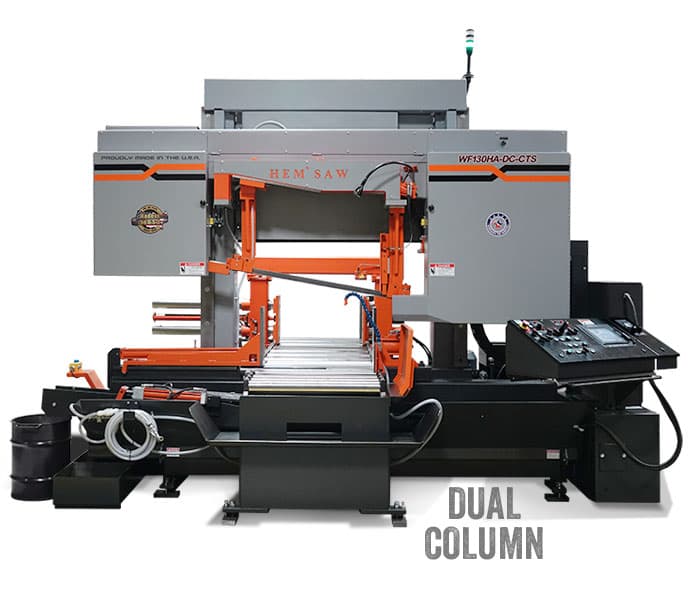

This saw is used by moving the wood against the blade. You can manipulate the wood in many different ways, including at different angles.