Band Saw Aldi

Band Saw 45 Degree Cut

First, this saw can be difficult to adjust. It's difficult to adjust things like the alignment, expandable workspace, and tensioning belt. This saw is difficult to move.

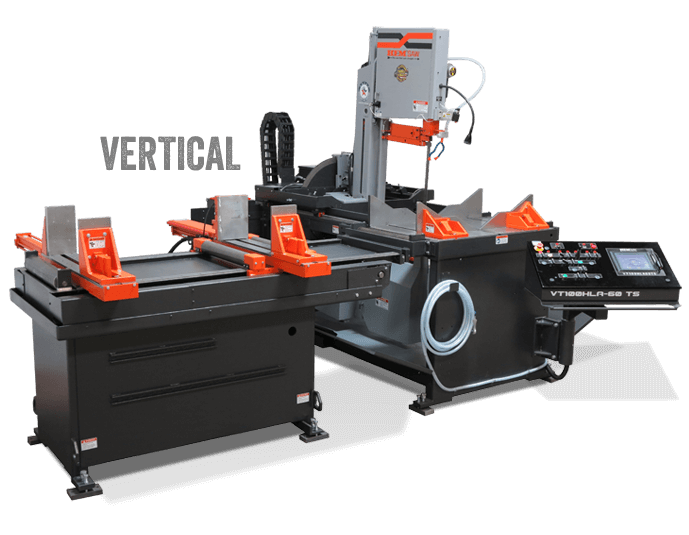

Precision balanced, the lower 9 spoke wheel and the upper 9 spoke wheel are coated with aluminum rubber for easy tracking.