Band Saw Cutting Fluid

Band Saw 3d Animal Patterns

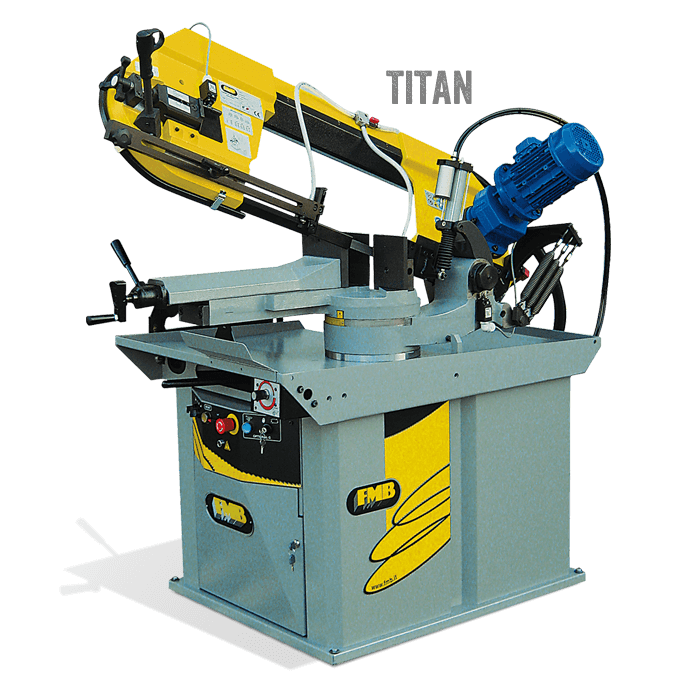

It is made from heavy gauge solid steel frames that are strong and durable. They also minimize vibration during operation.

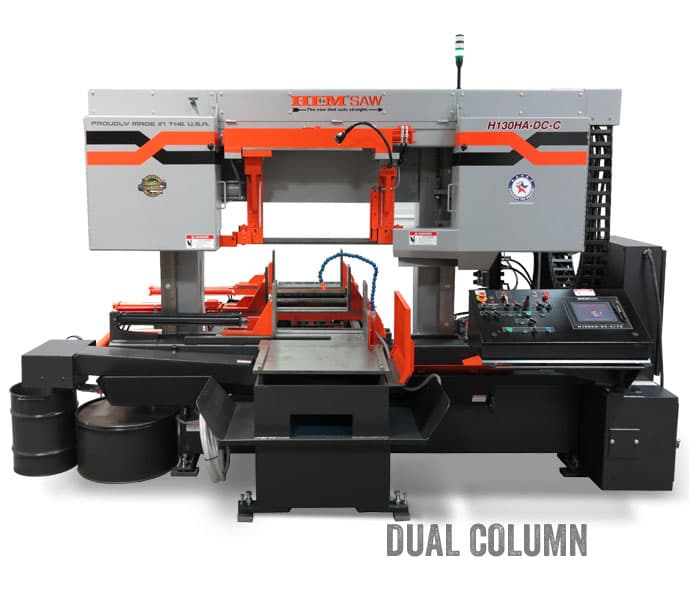

You can also buy a more expensive bandsaw. For DIYers, however, this will provide everything they need.