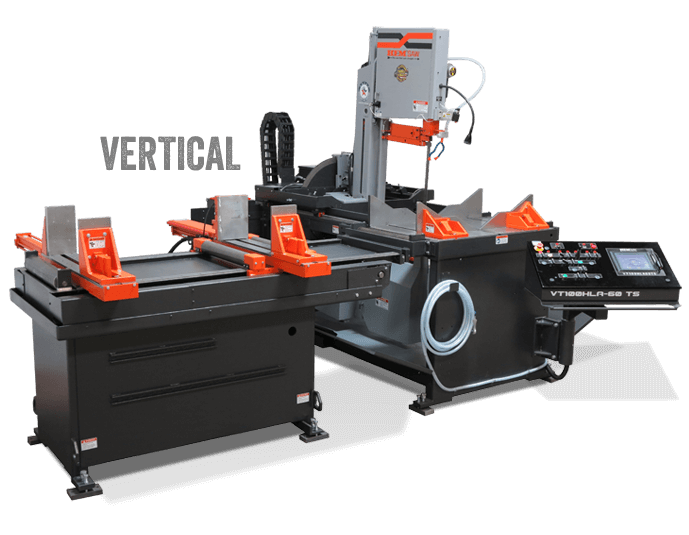

Band Saw Description

Band Saw 8x13

The most common use of band saws is woodworking. This machine can do amazing things with wood.

Most band saws come with an angle, fences, or table. These items will enable you make crosscuts as well straightcuts and miter cut, among other freehand options.