Bench Band Saws For Sale

14 Band Saws For Sale

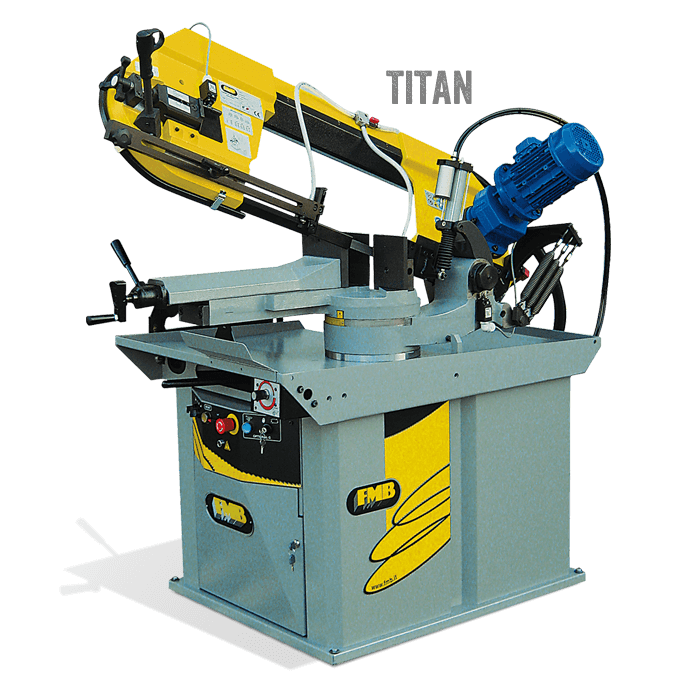

It's another heavy-duty machine, capable of professional use. It comes equipped with a builtin halogen light lamp.

The solid cast iron wheels of the upper and lower 15-inch diameters help to create the momentum required for heavy-duty resawing projects. You can use the included foot brake to stop the saw in an emergency.