Best Band Saws

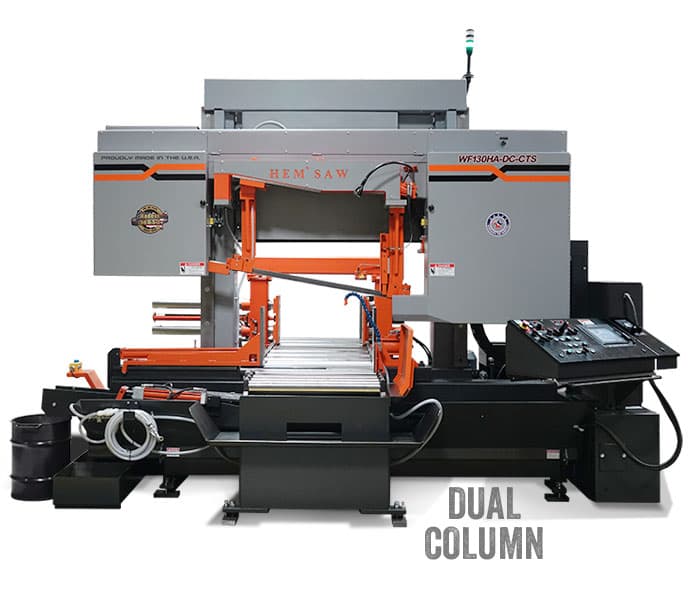

Cutting Bandsaw Machine

It became a priority for us to improve our blades. Everything changed when a new welding technique was created using advanced steel alloys and tempering techniques.

There are many options for different sizes and types available in the market for bandsaw blades. Each is suitable for a different use.

Best Band Saws