Robotic Coping Machines By Mtd

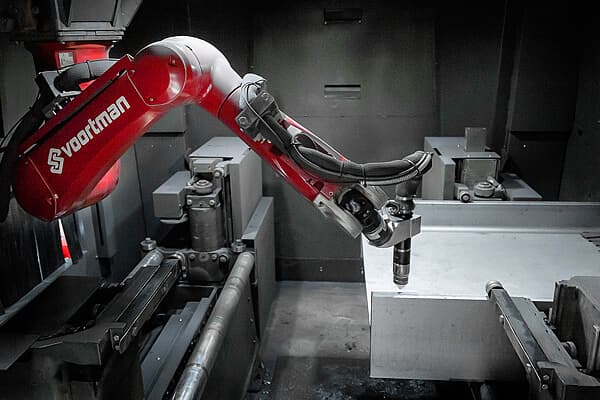

Gulf States Saw & Machine Co has been the market leader in 3D pipe profilers for over 35 years. We were the first to introduce a robotic beam profiling device with reliable profiling capabilities that can cut all slots, chamfers, and saddles: the RPC 1200 Mk3 A beam coping machine that can profile beams, channels, square tubes, angles bars, and square tubes has been a long-standing market demand. It also profiles pipes, plates, Tbars, and bulbs.

Because we are particular about making fabrication tasks seamless and efficient, we have here this Robotic coping and profiling beam that is designed to process angle bars, channels, square tubes, but als pipes, T Bars, plates and bulbs as well. With any of our Coping and profiling Robot, the possibilities of functions on your profiles/pipe cuts are truly limitless as it is an efficient tooling system unmatched in terms of the quality of its outputs. These outputs can be H, I and T beams, U and L channels respectively.