Ocean Challenger

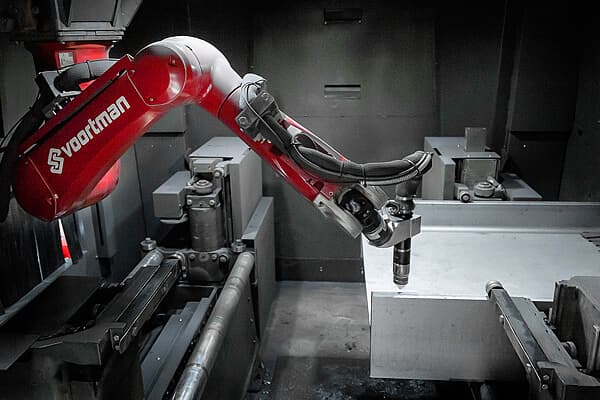

Voortman V808 robotic heat cutting machine is equipped the Panasonic TL-1800G3 coping system. It's faster and more versatile than ever. The robot's torch-nozzle is equipped with an accurate measuring sensor. The machine parameters automatically compensate the differences between the theoretical and actual dimensions to ensure the highest quality product. To speed up the process, the coping robotic only measures the sides that will be used.

We take pride in making fabrication tasks as seamless and efficient as possible. Therefore, this Robotic coping/profiler beam can handle all types of angles bars, channels and square tubes. Because it is an efficient tooling platform, our Coping/Profiling Robots offer endless possibilities in terms of how they can be used to cut your pipes and profiles. These outputs are H, I and T beams as well as U and L channel respectively.