E Robot

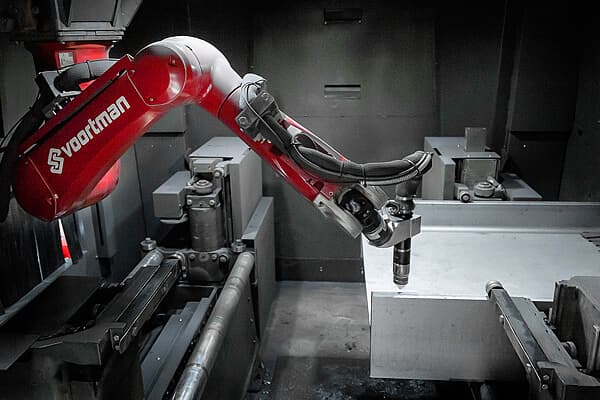

For those who may have questions as to the standards of our Robotic coping and profiling machine, we can confidently say that ours has scaled the most vital fabrication tests successfully; hardness, surface texture, beam flange weld access hole quality, bolt hole sizing, positioning and perpendicularity. As always, we have through our stocking made available the Voortman CNC coping and profiling machine, which is designed to an exceptional standard just for you, hence its outstanding capacities.

Bend-Tech Dragon A400 CNC tube marking, engraving, and cutting machine is commercial quality. Dragon A400, which is combined with the world's most powerful and efficient CAD/CAM Software, will deliver the results you need with speed and accuracy.