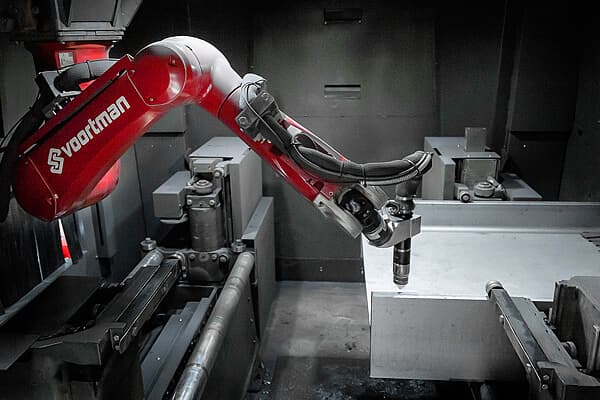

Robotic Coping Machines Llc

AFD CNC Flange and Plate Drilling Machine is able to drill 6 to 80 mm | 1/4� to 3-1/8� thickness within its own working area. Material is driven on the table with balls by fixing it with hydraulic clamping jaws. Material is positioned to the desired coordinates for drilling/marking/tapping by CNC program and then operation starts.

All it takes is one button to start your production. After importing industry-standard DSTV or DSTV+ files into our VACAM Software's processing list, your operator is free to focus on loading the system and unloading it. To keep up with production speeds, no manual intervention is required.