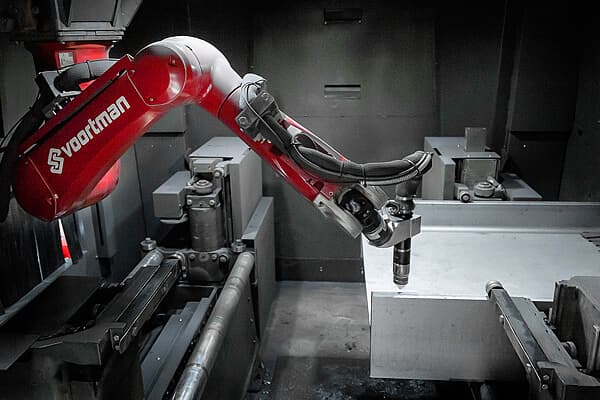

Robotic Coping Machine Melbourne

The integrated VACAD Editor gives your operators the ability to increase output by quickly creating new products or improving and correcting existing products. The interface is simple and straightforward with clear functionality. After just a few days training with Voortman Trainers, operators can take full advantage of VACAD Editors and VACAM.

Our Robotic Coping & Profiling system can be used to automate the fabrication processes of metalwork manufacturers and fabricators. It can work with various angles, beam drill lines and hydraulic punches. This is a simple way to increase the efficiency of your fabrication process from zero to 100!