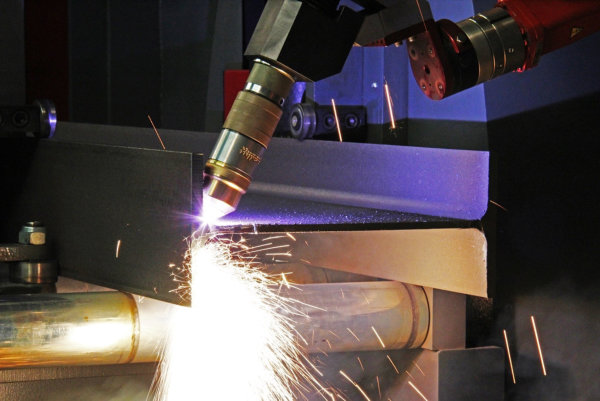

Beam Coping Machine Testing

Voortman makes it easy to upload a model of the cope to the CNC program from either the builtin shape library (CAD) or the shape library. The interface is user-friendly and allows you to manually calibrate cutting tolerances, nest pieces for coping, track robotic cutting paths, and even avoid mistakes. Voortman is ready to get to work. All that's required is to load the material and press the start button.

AKYAPAK provides an advanced solution to the steel construction industry once again... High processing speed and high performance with AFD upto 1000x1500 mm, 40"x60" materials.