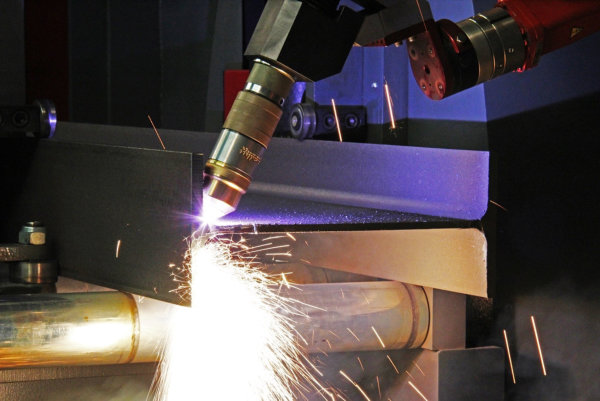

Robot Machine

Most importantly, many large fabricators have upgraded their 3-torch machines to a Voortman. This should tell you everything.

It's a 5-axis CNC robotic automated oxy-fuel cutting beam cutter that is very economical. This machine can be used to cut beams as well as channels, angles, plates, rectangular tubes, and channels. This profile cutter machine can easily cut any kind of material you can think up. It not only handles, but also cuts to length.