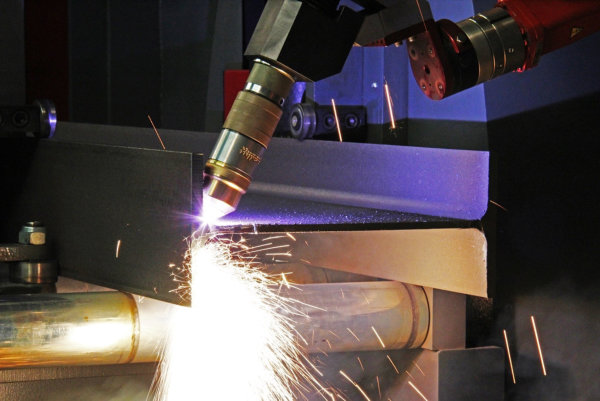

Steel Beam Coping Machine

In just a matter of days, your operator can learn how to use PCR42 plasma cutters. The interface of the PCR42 plasma cutter is very easy to use. Mac-Tech will be there to assist you if needed.

".. In the two-and-a half years that we have had a Voortman, both the efficiency and the quality of our product preparation has been greatly improved. The past process of weld preparation and handling was time-consuming. Manually burning and laying out the material left much to be desired. The Liberator makes it much easier to burn, and reduces grind time. The Liberator is small and compact, but it delivers great results. Ocean has allowed us to save both time and energy. This allows us to make more money, and also ensures that our customers receive a high-quality product.