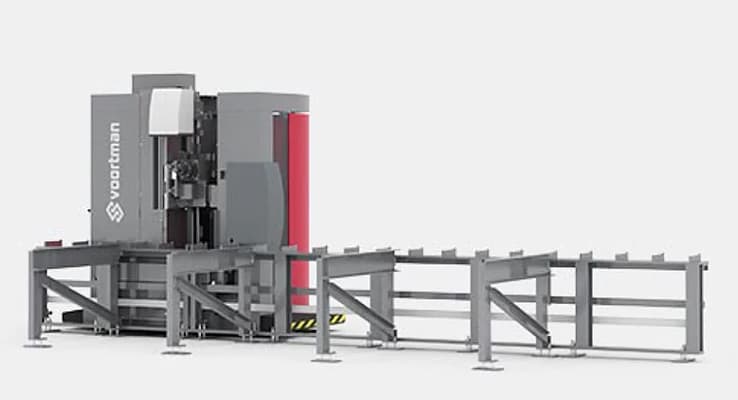

Material handling allows for the connection of multiple CNC machines. It keeps material flowing through the shop and allows fabricators expand their business. The Advantage-2 highspeed drill line processes 150 tons steel per 40 hour workweek. The ideal drill for small to large fabrication companies all over the world. All stops. Voortman has made the success for the steel industry his number one priority. Because of this, our support and service is unparalleled. Ask for a demonstration, quote, visit, or phone to learn more about some of the most formidable steel fabrication machinery. Voortman has more strength than steel.

Voortman offers 24 hour technical support for our global clients. Voortman's service personnel have many years of experience working in the field, assembly or factory checkout. This allows them to be familiar with all types of machines. Voortman has a service team that is available 24/7 to answer your questions.