Enco Drill Press

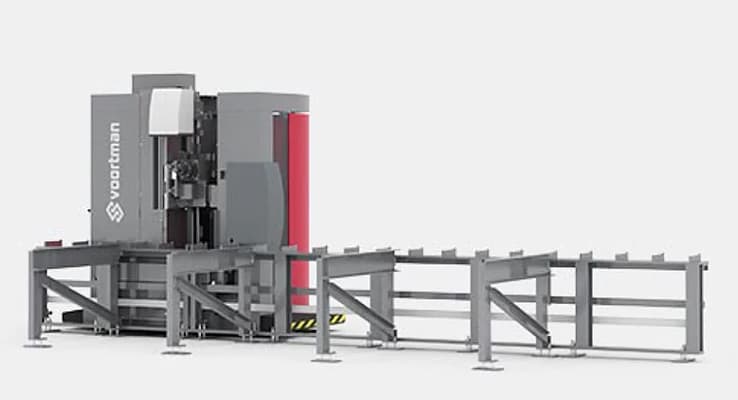

The CNC Drill Line is an extremely space-efficient beam processing solution as it only requires a floor space of 70ft x 9ft, making it ideal for even the smallest fabricator or fabricators with space limitations. We also have many CNC Drill Line installations that are outside, freeing up even more space for the fabricator.

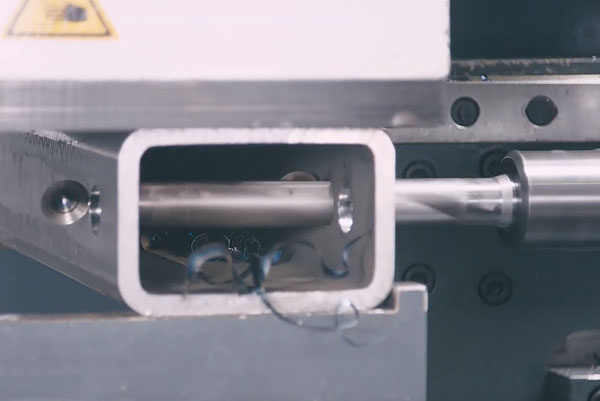

Voortman machines are world leaders in structural metal fabrication technology. Voortman machines give steel fabricators an edge in the industry. They have the ability optimize tonnage capacity. Advantage-2 CNC beam drill lines are the foundation of any structural steel fabrication workshop. This machine's core is high-speed, multi-spindle relentless carbide drilling. Advantage-2 is the most profitable steel industry drill line. The drill line's heavy steel frame will ensure that it can support shops for the long-term. Because of the roller feed design on both the infeed and output, the Advantage-2 can run profile end-to-end without stopping production. Each year, hundreds upon hundreds of metal fabricators use their Advantage-2s to produce steel in excess of tens of thousands of tonnes.