Cnc Drill Line Dead

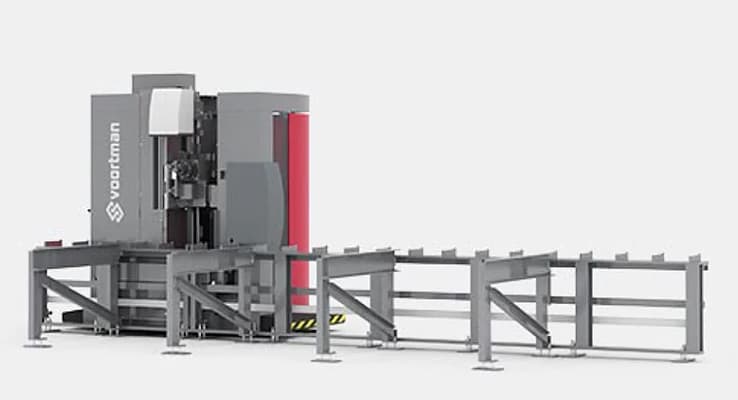

The CNC Drill Line can lay out and drill all of your holes in any type of steel profile in fractions of the time that it takes to do manually with a mag drill. It also marks all your welded attachments, eliminating the need to use a tape measure.

Project completion times are greatly reduced when you can mill. Combining Advantage-2's user-friendly Raptor 3DCAD/CAM Software, the operator can quickly program parts. You can view, modify, export and export parts information right from the 3D platform. Advantage-2 drills have many advantages, including the ability to scribe and mill slots and large lifting holes. This really sets the machine apart. We can use the scribing to create piece marks, layout lines and center points. That flexibility to use it when and how we choose has been amazing.