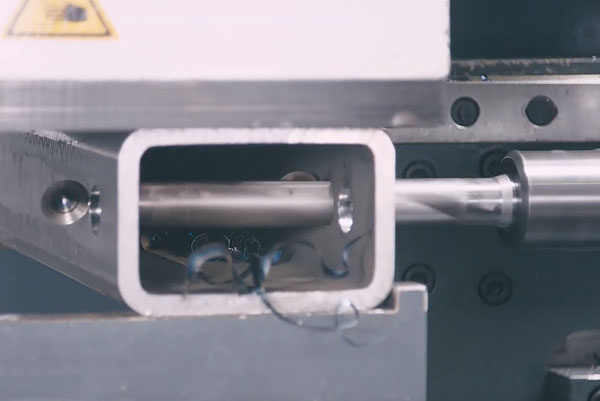

This range can move along the profile easily and offer a wide range of automated functions. It can process I andH beams, channels and flat bars, angle irons, channel, rectangular tubes, square tubes, and T bars respectively. Automated processing of already assembled metal profiles is possible without the need for programming.

Since 1950, we have been designing machines and solutions to help you as a steel fabricator. Automation is our response to ever-decreasing labor availability and rising labor cost. We can help you lower production costs and improve your margins. Voortman's CNC Beam Drill line can guarantee the highest productivity, accuracy, reliability and quality. Our CNC Beam Drill Lines include many functions, including drilling, milling and marking as well as countersinking, thread tapping, and other functions to optimize productivity and increase automation. Voortman has a wide range of Beam Drill Lines to suit every production and company.