Time

Voortman's service technician will finish calibrating your machine and spend time with you, your operators. He will then take them through our easy-to-understand training program. You will receive instruction in:

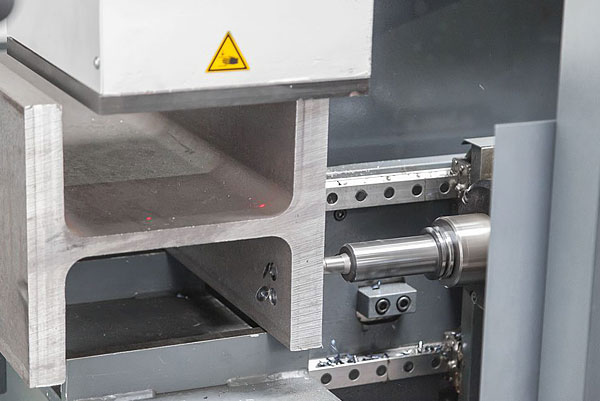

The CNC Drill Line is the most affordable CNC beam drill line on the market today and ensures that the fabricators is the low-cost producer, allowing him to win more work and to make more margin.