Material

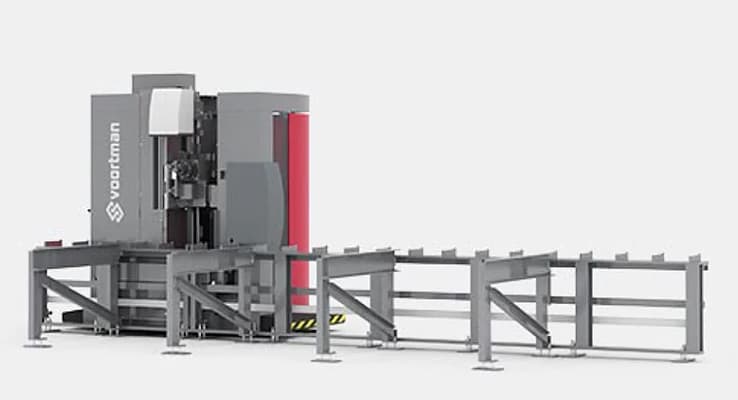

Voortman is the man behind today's CNC beam drilling line standard. He has used time-tested technology. Advantage-2 processes 150 tonnes of steel per week on average. It is the most efficient way to drill, mill, tap, and countersink.

Voortman technicians will complete the installation and calibration of your machine. After that, he'll spend time with operators and guide them through our comprehensive training program. Training will be given to your operators in: