Cnc Drill Line Oz

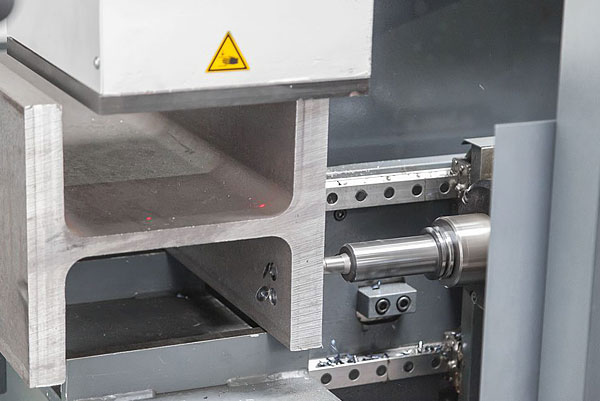

These drop in serrated grippers can be used to secure base plates and flat bar profiles, as well as angle and other profiles that may have rounded edges which want to push away at the datum line.

We have been creating machines and solutions for steel fabricators for 50 years. As a result of the decreasing ability to find qualified labor and rising labor costs we focus on automation. This will allow you to lower your production costs and increase margins. Voortman's CNC Beam Drill Lines will ensure that you have the highest level of productivity, accuracy, and reliability. Our CNC Beam Drill Lines combine many functions such as drilling, marking, countersinking and thread-tapping to maximize productivity and automate your workflow. Voortman offers a complete line of Beam Drill Lines that can be used for any type of production.