H Beam

This adaptor for the Morse Taper Morse Taper drill bits allows you to use standard parallel shank bits when drilling smaller diameters. It can drill a maximum diameter of 12mm and a minimum diameter of 3/64'' (1mm). Maximum drill diameter is 12mm, minimum diameter is 3/64'' (1mm).

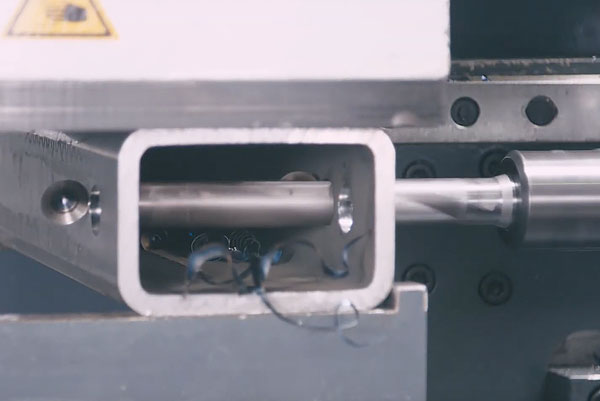

Project completion times are greatly reduced when you can mill. Combining Advantage-2's user-friendly Raptor 3DCAD/CAM Software, the operator can quickly program parts. You can view, modify, export and export parts information right from the 3D platform. Advantage-2 drills have many advantages, including the ability to scribe and mill slots and large lifting holes. This really sets the machine apart. We can use the scribing to create piece marks, layout lines and center points. That flexibility to use it when and how we choose has been amazing.