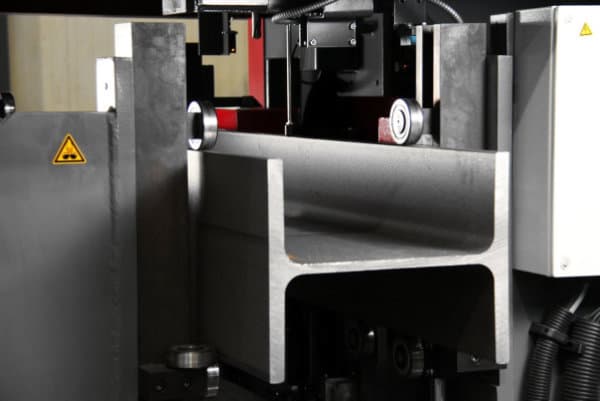

Cnc Beam Drill Line Up

GSS Machinery will provide you with as many options as you need when drilling with your CNC Beam Drill Line.

Voortman is known for its dedication to service and support. It is the industry's gold standard. Voortman provides a global team for customer support that is available 24/7 at the Voortman Customer Support Center. Voortman supports you with state-of-the art remote diagnostic software, local field support and an industry-leading warranty.