Cnc Beam Drill Line Manual Pdf

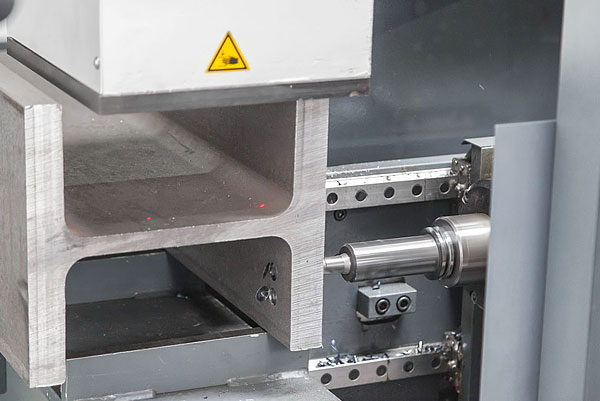

Voortman has shaped today�s CNC beam drill line standard with time-tested technology. The Advantage-2 processes an average of 150 tons of steel per work week with the most efficient drilling, milling, scribing, tapping and countersinking operations.

Voortman built the CNC Beam Drill Line only for GSS Machinery. Voortman manages the installation, warranty, service and maintenance of the CNC Beam Drill Line. Voortman is the service provider. GSS Machinery is available to help if needed.