Labor Costs

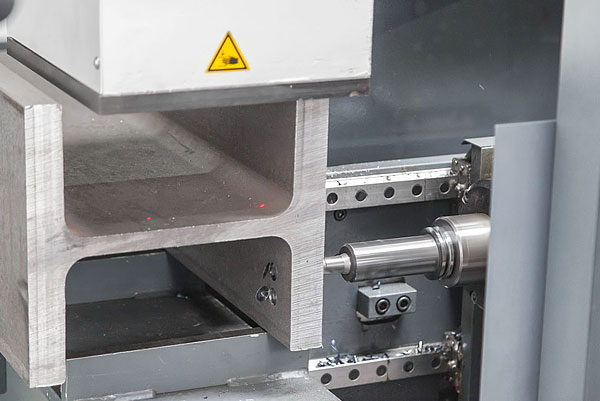

Voortman�s roller feed measurement system exceeds industry standard. It is important to maintain accurate measurements without hesitation during production. Even though there may be slight deviations in the material, accuracy should not be compromised.

The CNC Beam Drill Line is the most affordable CNC beam drill line on the market today and ensures that the fabricators is the low-cost producer, allowing him to win more work and to make more margin.