Spade Bits

An attachment that marks 4-axis locations eliminates human error during manual layout. Even after painting blasting or galvanizing, the part information is still retained.

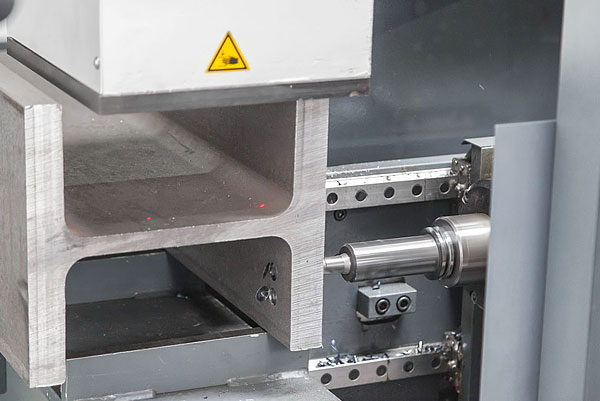

Automatic Edge Finder - This edge finder can either be used manually (Jogging Mode & Screen Button), programmatically with M & G codes, or fully automated as a dedicated program. This option allows you to adjust offsets and rotate the program to match the orientation and position on the cutting table.