CNC Beam Drill Line Alabama

The CNC machinery you choose to purchase can be a Vertical Machining Machine or a CNC routing machine. These two pieces can be used to accomplish many different things. Which one should you...

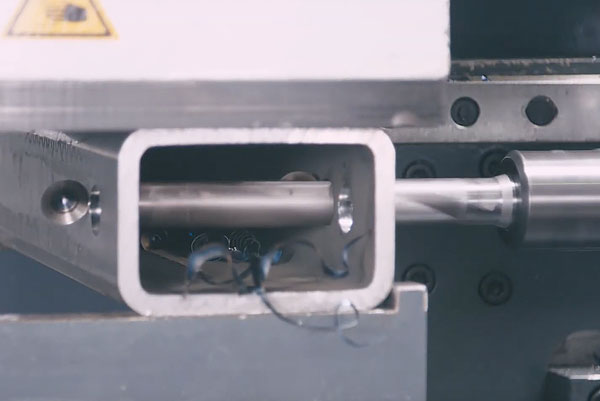

AC Unit Mounted on Electrical Cabinet. The unit is located on the cabinet's High-Power (480v) side. It is located close to where the drives are installed. This allows for faster heat dissipation and keeps the cabinet's temperature stable. All axes have servo drives that are the main contributors to heat in the electrical cabinet.