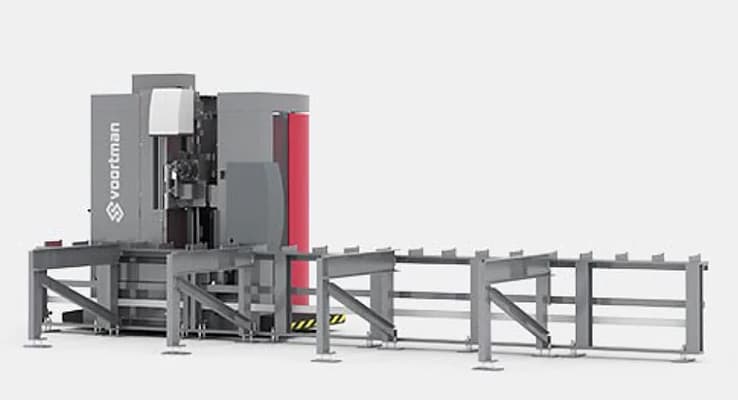

Cnc Drill Line Zam

".. ". It has been easy to assemble the truck frames without any errors due to its repeatability and accuracy. Avenger drills channels for one truck in under two hours. This is compared to 16 hours if we had to do it manually. The machine has significantly increased our productivity and profitability !.."

A 4-axis layout attachment eliminates human error from manual layout methods. The part information can still be used after blasting, painting, or galvanizing.