Material handling allows fabricators to connect multiple CNC machines and keeps material moving through their shop, allowing them to grow with the business. The Advantage-2 high speed drill line can process up to 150 tonnes of steel per 40-hour work week. This drill line is ideal for small and large fabricators all over the globe. Stop. Voortman is committed to the success of the steel industry. Our support and service are unmatched. To learn more about the most powerful steel fabrication machinery, request a demo, quote or visit. Voortman is stronger than steel.

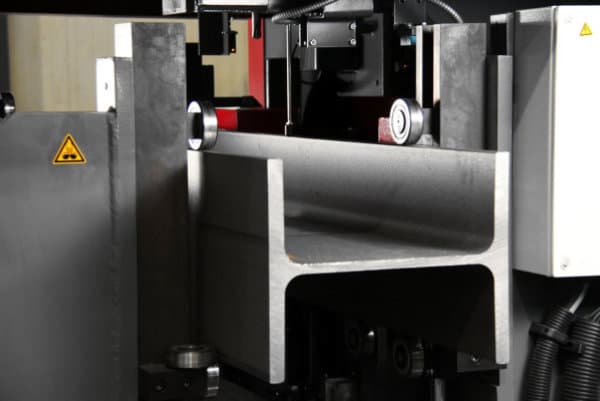

Each of our beam drill line machines have linear guides, central lubrication, and a tool cooling system to ensure smooth operation and lower maintenance. Within each coordinate system there is a 4 station tool changer, allowing it to drill, mill, scribe, counter sink, or tap as needed; tools can even be swapped out mid-operation easily and without disruption. Positive beam positioning consists of an arm attached to a rack and pinion system on the feed conveyor to more accurately position the beam as it goes through the drill line, maintaining .004�, making our steel beam drill lines much more accurate than friction roller machines.