Cnc Drill Line Orchard

GSS Machinery has provided us with the best support possible in steel fabrication markets, which is something I am proud to say.

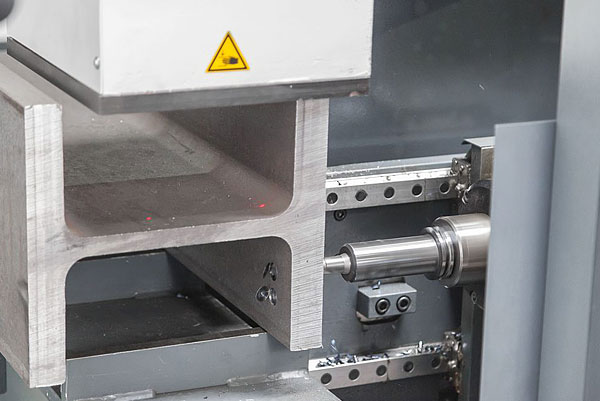

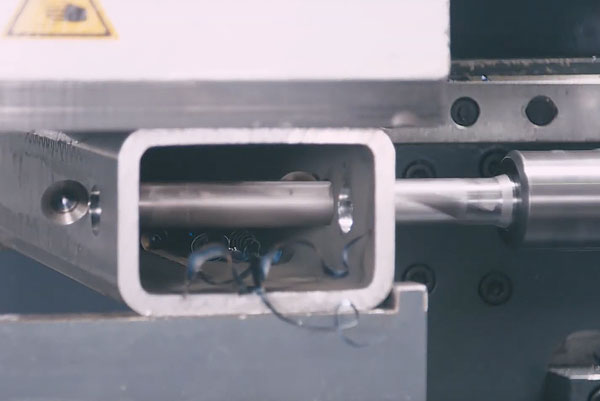

Material handling is a way to tie together multiple CNC machines. It also keeps material flowing through a shop, which allows fabricators grow their businesses. The Advantage-2 high-speed drill machine can handle 150 tons of steel in an average 40-hour week. This is the ideal drill line for small- to large fabricators around the world. The end. Voortman places the success of steel industry as its top priority. We are proud of our unsurpassed service and support. Call, request a demo or quote to find out more about the best steel fabrication machinery. Voortman is the name of our company and we are more powerful than steel.