Roller Feed Measurement

CNC Drill Line offers the most affordable CNC beam drilling line available today, which allows the fabricators to win more jobs and make more margin.

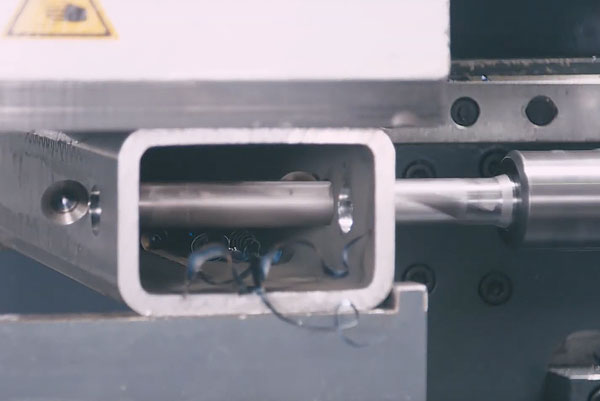

The MultMaster works as an extension of the Roller Feed measurement system in order to perform cuts which may otherwise require manual positioning for programs with many small pieces. This accessory allows fast and simple material processing on a Voortman drill and saw tandem system by automating the processing of short remnant sections.