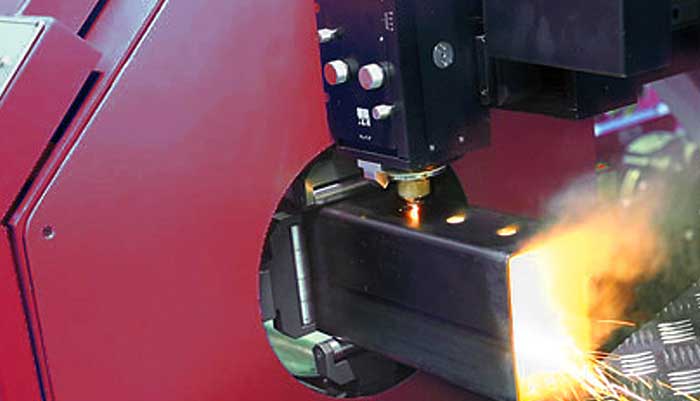

Tube Laser Cutting Systems 500w

Variety is the reality of any job shop, and the same goes for those that operate a tube laser. It’s not unusual to see parts of various sizes come from one tube. The machine must be able to unload laser-cut parts that may be as small as 2 in. and as long as 15 ft., one right after the other. It also must be able to unload those parts without damaging them, which can be a challenge with softer metals such as aluminum.

Motion Dynamics is a leading manufacturer of neurological sub-assemblies, including steerable catheters and “pull-wire” assemblies, making use of our StarCut Tube machines for precision cutting of key components.