Tube Laser Cutting Systems Reno Nv

Leaders in advanced laser-cutting solutions and CNC controls.

Laser tube cutting at home doesn't have to be complicated or expensive. Students and engineers alike can cut like never seen before

Square

Find laser systems for electronics production that can perform high-precision, fast cutting, welding, marking and ablation of metals or plastics.

StarFeed, an automated loader/unloader of the StarCut Tube Laser Cutting Machine, is available in sizes S & L. This allows for fully automated dry or moist cutting tubes with diameters between 1 and 20 millimeters. StarFeed L holds up to 48 tubes. It also allows for the processing and storage of oval tubes. Its sensor-controlled gripping unit avoids damage. It results in a huge increase in productivity.

With a rock-solid cutting platform (the SL uses a mineral cast base) these machines offer the ultimate in precision, with contour cutting accuracies better than +/- 5 µm. A choice of fiber laser or the latest Monaco USP laser enables fine cutting of any polymer or metal.

Learn how the Coherent StarCut Tube was used to cut stents and how StarFiber, a laser-powered cutting machine, helped NPX Medical.

Leaders in advanced laser-cutting solutions and CNC controls.

Laser tube cutting at home doesn't have to be complicated or expensive. Students and engineers alike can cut like never seen before

The simplest way to enter the tube laser cutting world. Tubes up to Ø 4,72" (120 mm)2D cutFiber laser

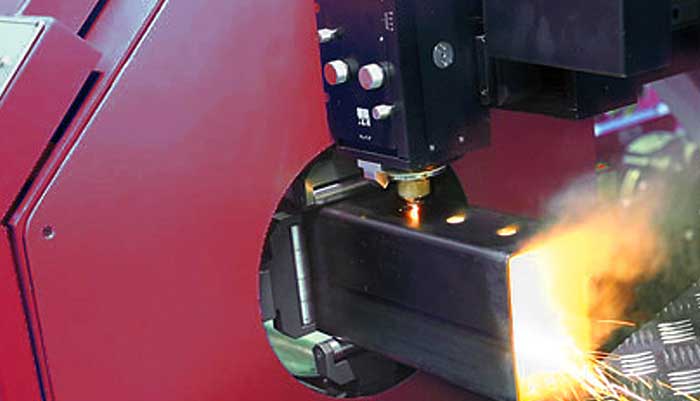

All types, all forms: This three-dimensional cutter machine will cut carbon and stainless steel, aluminum, and red metals in all shapes and sizes. It can be used to cut irregular, round, square, rectangular, and rectangular shapes.

Many applications are possible for processed tubes or profiles. There are many applications for processed tubes and profiles, whether in the automotive, furniture, architecture, petrochemical, or commercial vehicle building. Many industries have embraced laser-assisted manufacturing of tubes and profiles. This allows for a virtually unlimited range of components and unmatched design possibilities.

The CO2 resonator requires much more energy and is larger. Electricity is used to combine gases to create the laser beam. Mirrors aid in the light's intensity and prepare it for exiting the resonator. The beam must travel along a path that includes several cooled mirrors to reach the lens after it has exited the resonator. This causes the beam to lose power and quality.

StarCut Tube L 600 has a choice of three laser options: a fiber laser or a USP. StarCut Tube SL has the smallest footprint of any model on the market.

When making fitness equipment, the most important components are durability, usability, compactness, and design.

You can choose between 2D or 3D laser cutting technology, which allows you to create parts with a very specific shape. This includes tubes of various shapes, such as squares, rectangles, and profiles with different open cross-sections (e.g H, L and Tcross-sections). The 3D technology allows for bevel cuts of up to 45 degrees. This flexibility eliminates the need to do costly milling, drilling, punching or sawing.

The subject of material loading and unloading automation is well established in sheet laser cutting with a multitude of solutions and complexity. In contrast, tube laser cutting systems equipped with vertical storage systems, for tubes and section bars, capable of handling bars automatically and allowing for unmanned production changes have only been available for a few years.