Tube Laser Cutting Systems Working Principle Pdf

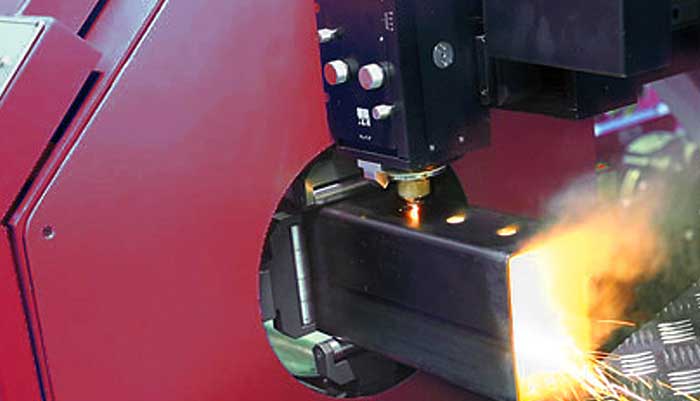

Fiber lasers are nearly maintenance-free and demonstrate superior wall plug efficiency compared to traditional CO2 Laser cutting machines. They can also be used for precise cutting of reflective materials. They are faster than CO2 when cutting certain thicknesses of steel. The speed of cutting tube is relative. Real time savings can be achieved by speeding up processing times for the tube and creating finished parts.

The application of processed tubes and profiles is manifold. Whether in the automotive industry, furniture design, architecture, petrochemical industry or commercial vehicle construction. In many industries, the laser-assisted processing of tubes and profiles offers an almost unlimited manufacturing spectrum for components and unique design possibilities.