How do you cut a tube in half lengthwise

Let's now look at the benefits associated with an automatic tube and section-bar storage system combined with a Lasertube Cutting system.

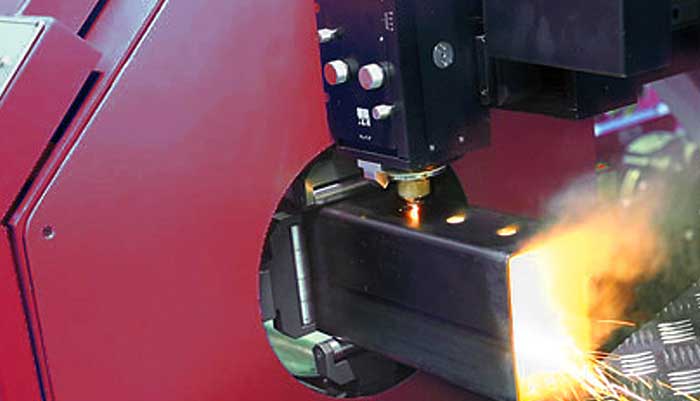

We offer you the ideal solutions for the world of laser tube cutting. Find out here how lasers can eliminate entire process steps while also increasing the range of parts you can produce.