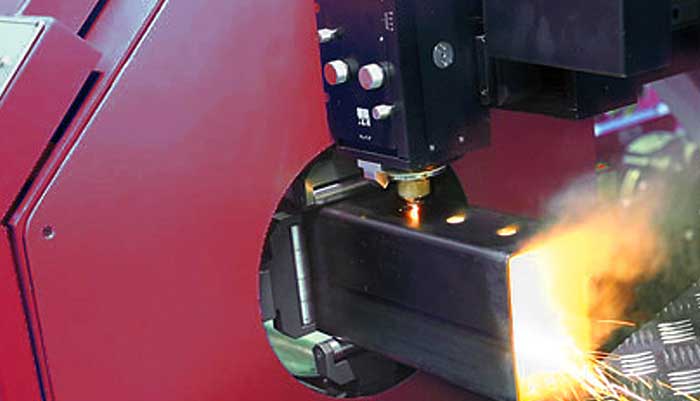

Tube Laser Cutting Systems Engineer

Keep in mind that there is no such thing as a perfect tube. They have bows. Weld seams can protrude not only on the exterior but also the interior of the tube. Itís a real challenge to process this material consistently and rapidly when such inconsistencies exist from one product run to another.

Parts are held by automatic tabbing (do in FabCreator) and a set jaws on both the idler and drive chuck.