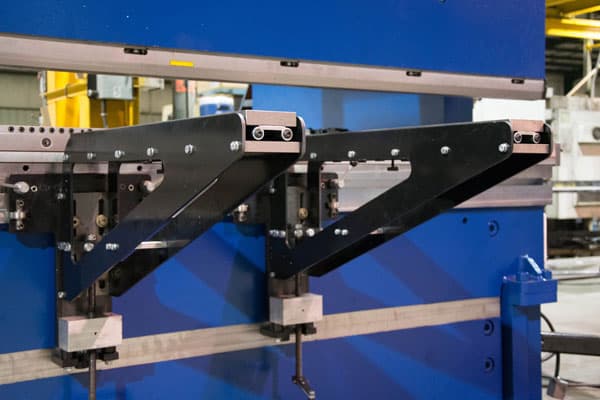

Dual Cylinder Press Brake Attachment

Dual Cylinder Press Brake No

Finally, there is a press brake solution for heavy duty that is both user-friendly and loveable.

It is powered by a double-axis back gauge and can perform automated bending steps calculation. These servo-electric press brakes are very precise in bending and eco-friendly. They also require minimal maintenance.