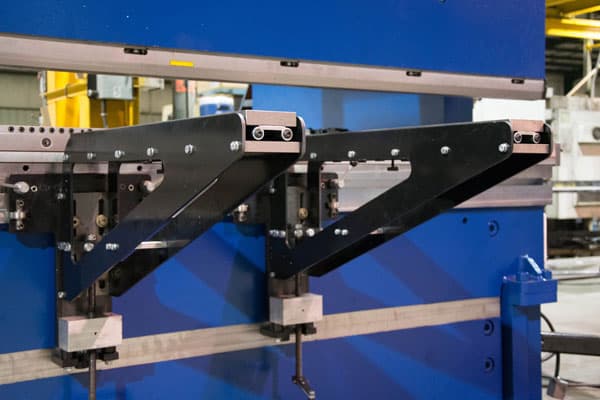

Dual Cylinder Press Brake Hemming Dies

Dual Cylinder Press Brake Band

A fully automated press brake system can help relieve pressure on production lines if deadlines and timelines are pressing. How do you make it work?

At Gulf States Saw & Machine.Co , we carry a wide variety of hydraulic press brake models to meet the unique needs of the various businesses we serve throughout the country. Our press brakes range in size from 22 tons to 440 tons and bed lengths from 4’ to 13’ with CNC or manual controls. In addition to our standard inventory, we can accommodate custom orders for specialty length requests and tonnage. All of our press brakes include safety devices and a rear safety cage that disables the machine when opened for easy and secure maintenance. All electrical components use industry-standard parts, which are readily available in our Memphis, TN warehouse. Download a pdf for more details on each model.