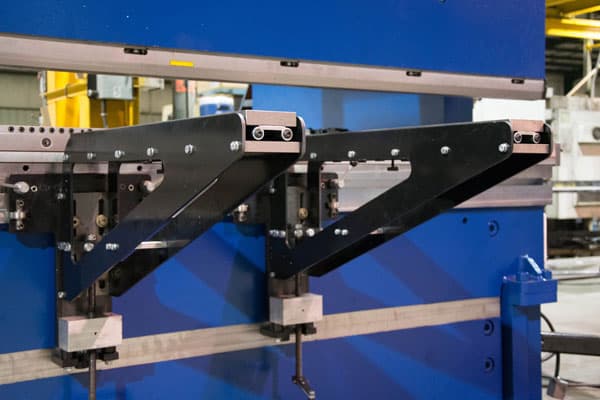

Dual Cylinder Press Brake Kokomo

Press Machine's

This game-changing tool changer provides real-time information that allows any press brake operator to perform better.

Hydraulic press brakes are hydraulically applied to the ram to reduce its height, rather than relying only on mechanicals. They may contain more than one cylinder, giving the operator more control over the bend. It produces a precise and configurable bend. The hydraulic press brakes are similar to mechanical presses but have some disadvantages. Hydraulic press brakes cannot exceed the rated tonnage. You may prefer mechanical press brakes if you need flexibility.