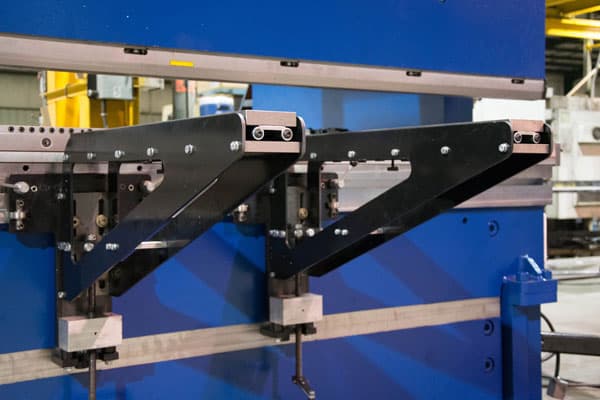

Dual Cylinder Press Brake Japan

Controller

It's obvious that press brakes can be a very useful tool for industrial-grade metalworkers. Do you need a press brake for your business? Gulf States Saw & Machine. Co offers everything you need to make your business a success.

If timelines and deadlines are pressing in on your production line, a fully automated press brake solution can go a long way toward relieving some pressure—on both your bottom line and your peace of mind. But how?