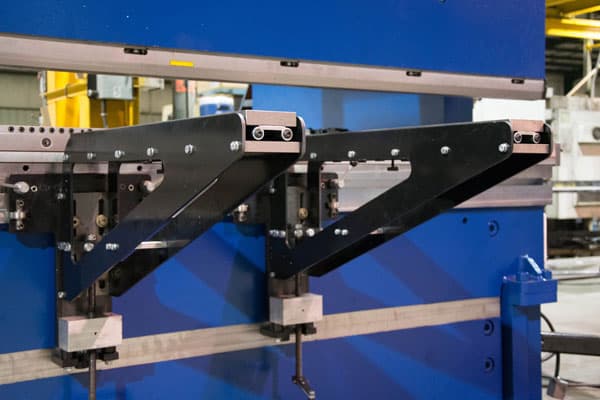

Dual Cylinder Press Brake Blazer

Dual Master Cylinder With Proportioning Valve

Automated press brakes can ease the pressure on your production line if there are deadlines or timelines that must be met. How can you do this?

Other elements should be taken into account when calculating this margin, such as the thickness of the punch blade, the length of the fold and the opening of the V.