Dual Cylinder Press Brake Funeral

Bending

There are two ways press brakes can bend metal. The first is called bottom bending because the ram will press the metal to the bottom of the die. Bottom bending results in highly accurate bends and relies less on the press brake machine itself. The downside is each tool is they're made to create one specific bend, so you’ll need to purchase a new one for every angle you want to make. Air bending leaves an air pocket between the ram and the bottom of the die. This allows the operator to accommodate for any spring back the material might provide. These types of dies only need to be changed if the material’s thickness is too much. Air bending’s drawback is the accuracy of the angle is affected by the material’s thickness, so the ram needs to be changed out accordingly.

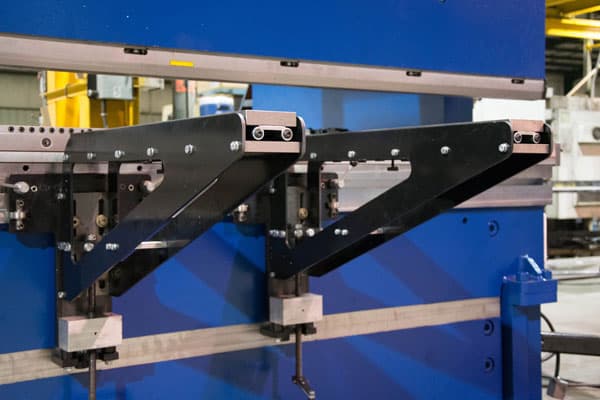

Hydraulic presse brakes are great for heavy-duty tasks and can be customized to suit any customer's needs.