Co2 Lasers

The laser beam generated by the amplifier is then fed to cutting heads using a flexible optic fiber.

Amazon doesn't offer a return policy. But, they will provide a 30-day replacement guarantee if you buy through Amazon.

The fiber laser's small focal size allows for laser light to be focused with high intensity. It is an excellent choice for permanent high contrast engraving applications.

MCWlaser Pro is intended to be used on metals such as steel or stainless steel, silver or copper, alloy, aluminium, etc.

Laser modules have a lifetime of more than 100,000 hours. They can be used to engrave with repeatable precision of +0.00039".

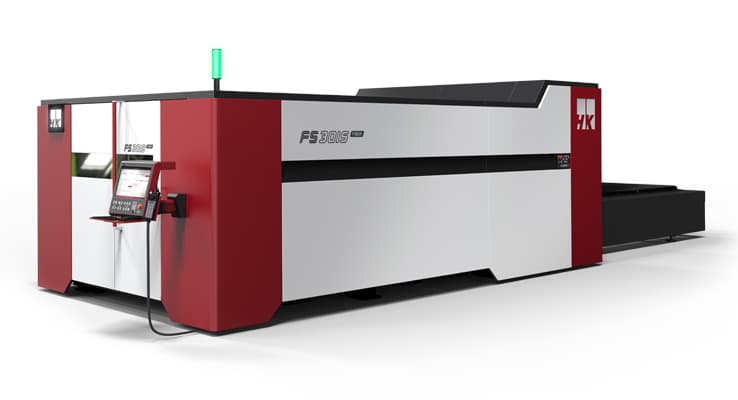

Fiber Lasers from Gulf States Saw & Machine Co. allow for consistent, precise cutting of metal and can be used to greatly improve quality and production.

The laser beam generated by the amplifier is then fed to cutting heads using a flexible optic fiber.

Amazon doesn't offer a return policy. But, they will provide a 30-day replacement guarantee if you buy through Amazon.

FM-Desktop also offers an option to increase the marking area. It can be extended to 7.87"x7.87", or 11.81x11.87".

This laser is a pulsed laser fiber laser with 1064 nm wavelength. It has a life expectancy of approximately 25,000 hours.

For effective engraving with such lenses, you can mount Muse Pandora underneath an adjustable desk.

Triumph Laser includes a computer with rotary axis and foot switch, a 200mm lens, laser glasses, and a wrench for use with the 30W desktop fibre laser.

The laser used in this experiment is a pulsed-fiber laser with a wavelength at 1064nm. It has an estimated life span of more than 25,000 hours.

Unlike CO2 lasers, fiber lasers consume much less energy and operate at a shorter wavelength ranging between 780 nm and 2200 nm, giving a much higher absorption rate.

High speed IPG fiber laser cutter is type of high power laser metal cutting machine with 12000W power supply for commercial use of thick metal fabrication including stainless steel, carbon steel, mild steel, tool steel, brass, copper, aluminum, alloy, and rare metals in industrial manufacturing.

Fiber lasers on the other hand can cut through reflective materials if the have enough power. They can pretty much cut through any kind of metal with enough power. They will only be limited by how thick they can cut.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.