Fiber Laser Welding Machine Aliexpress

Fiber lasers are much more efficient than CO2 lasers and use less energy. They also operate at a shorter wavelength, between 780 and 2200nm, which gives them a higher absorption rate.

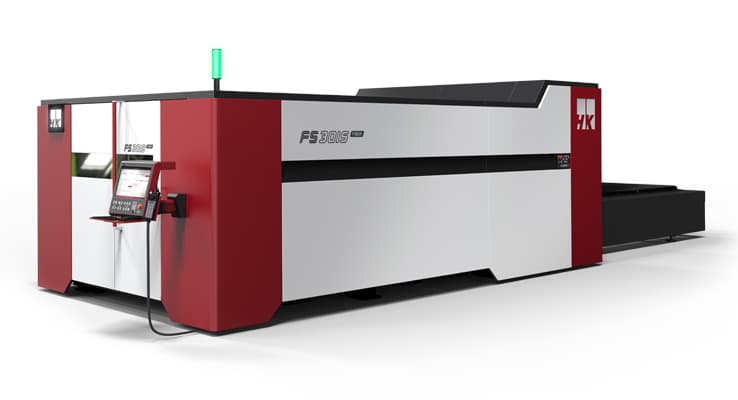

Fiber lasers are changing the industry in laser metal cutting with their low maintenance and high cutting efficiency.