Fiber Laser Machinery 4-axis

Fiber lasers utilize laser light to stimulate the active medium.

MCWlaser PRO split-type machines are those that have both the laser source or the engraving device in separate parts.

Galvo heads can also be used to work at extremely high speeds when added to the machine. Galvo head are often used in portable laser-engravers.

Fiber lasers are widely used in engraving applications, and their wavelength ranges between 780nm - 2200nm.

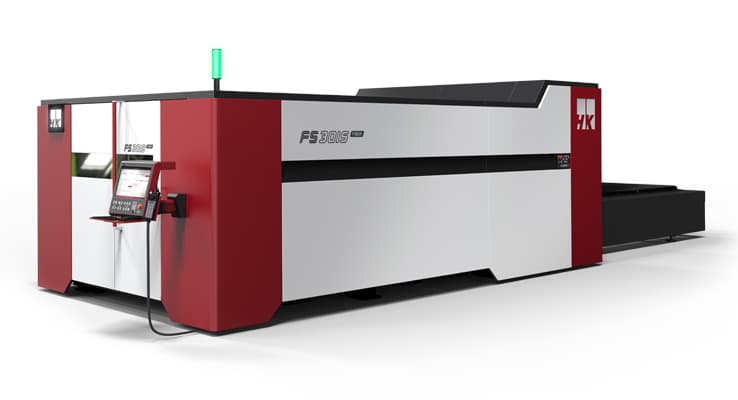

Affordable 5x10 industrial fiber laser metal cutting machine ST-FC3015LR is used for metal tube cutting and metal sheet cutting all in one. Now the industrial 5x10 laser sheet metal & tube cutting machine for sale at cost price.

It will be able to run at the recommended speeds and power rates for steel, aluminum, black acrylic and lexan as well as granite and other materials.

Fiber lasers utilize laser light to stimulate the active medium.

MCWlaser PRO split-type machines are those that have both the laser source or the engraving device in separate parts.

Laser cutting machines have the advantage of being able to accurately cut metal. They are 2X more precise than plasma cutters. Plasma lasers can cut metals up to 0.1mm or.004inches. Laser cutters are capable of cutting metals up to.05mm, or.002inches.

The High Speed SKYWAY delivers all of the cost saving advantages of the previous sorting system, but with unmatched performance.

High precision lenses are used to collimate and increase the energy density in laser machines equipped with fiber laser sources.

Gulf States Saw & Machine Co.'s FM1212-50S comes unassembled. You can attach it by reading the user manual.

At the same time, the high-precision 3D robot fiber laser cutter has important strategic significance for improving the level of aerospace technology equipment. As the laser volume becomes smaller, the power increases and the auxiliary devices continue to improve for thick plate cutting and large format metal fabrication. The laser generator, power supply, host, control system and cooling circulation device are closely combined to form a complete set of compact laser cutter with small footprint and perfect function.

Our machines are capable of cutting steel, brass, aluminum and stainless steel without fear of back reflections damaging the machine. By using these fiber laser machines, you�ll reduce your maintenance requirements and cut your operating costs considerably.

A fiber laser's heart is the source of the laser beam. It does not include any gaseous media like a CO2 or CO3 laser.

Fiber lasers absorb much more energy than CO2 Lasers.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.